Application of the static pressing steel pipe pile in reinforcement of basement

1.0 Introduction

This new project is the anti-aircraft basement. The ground floor is a supermarket and commercial zone, and the storey height of this floor is 4.2m. The second floor underground is used for parking with the storey height of 3.6m. This project takes 0600PHC prestressed pipe pile, and strongly weathered siltstone is used as the bearing layer. For this foundation, it is piled raft with a thickness of 650m. In 2012, under the influence of super typhoon, it rained heavily for seven days, causing the water level in the site rose rapidly. After the storm, it was found that there were apparent cracks and water seepage in the floor of the second floor underground. It is judged that there is an overall floating accident in the area about 1000 m below the second floor underground.

2.0 Treatment scheme on basement floating

2.1. Analysis of causes

Through the discussion among designers, construction sides, project supervisors and relevant experts, it is conducted that the up-floating of groundwater causes up-floating of the basement. It is also the resulting structural cracks to the bottom floor. The original design adopts prestressed pipe pile to bear the resistance to avoid to be pulled out. This project takes a method called releasing water buoyancy. Namely, according to the rolling situation in the floor of the basement, sand and gravel are backfilled within 4m at the bottom of the outer basement wall. It will form a continuous horizontal permeable layer, flowing into the drainage system. This treatment makes the designed anti-uplift water level lower.

However, the porous layer plays a limited role when the actual flood comes. It will cause the water level to rise rapidly, exceeding the designed anti-floating water level. The overall floating of the local basement is induced.

2. 2. Reinforcement treatment scheme

Emergency anti-floating treatment:

Precipitation well is arranged around the basement to pump water and reduce the height of groundwater level continuously. Sandbags are placed on the basement floor, piling up 2 m to increase the dead load of the basement floor. It does not only resist the whole rise of the basement, but also contribute to the reset of the arch floor. The basement floor shall be permanently reinforced after the restoration. The original pile foundation adopts the 0600PHC prestressed pipe pile with strongly weathered siltstone as the bearing layer. The length of this pile length is about 47 m, and the characteristic value of single pile bearing capacity is 1200 kN. Since the original pipe pile has been broken, the compressive reinforcement of pile foundation under the original column and the overall anti-floating support of basement shall be considered for permanent support. According to the storey height of the basement and the construction conditions, the static pressure steel pipe pile is adopted for support. This construction process is flexible and straightforward to move, which can adapt to the requirements of small space. Also, according to the needs of bearing capacity, the pipe diameter can be adjusted to meet the needs of stress.

3.0 Steel pipe pile reinforcement scheme

3.1 Design of steel pipe pile

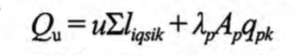

The soil at the basement floor is No. 2-1 sandy, silty soil layer with a thickness of 3.0 ~ 6.0m. The layer below that is mud clay, which is the combination of No.5 clay layer and No.7-1 silty clay layer. Weathered siltstone works as the supporting layer for the original pipe piles to pass through the clay layer. The original pipe pile penetrates through the clay layer with weathered siltstone as the supporting layer. Since the pressing strength on the static pile is limited, the 7-1 layer is set to be the bearing layer temporarily. A commonly used DN350 seamless steel pipe with the external diameter of 377mm and the thickness of 100mm is adopted in this project. Four bearing piles replace the original prestressed pipe pile, and vertical endurance value features for steel pipe piles, Qu, is set to be 600kN. According to JGJ 1994– 2008 technical specification for building pile foundation, the formula for the estimation of the vertical bearing capacity of single steel pipe pile is as follows:

λp is the coefficient of plugging effect at the pile end, which is equal to 1 in this case Ap is the size for the steel pipe pile, which is 0.112 m2.

According to equation (1), representative geological sections are selected for calculation. The length of steel pipe pile required is calculated to be 42 m, and it has to be inserted into the bearing layer, 7-1 layer, no less than 2m.

According to equation (2), prestressed pipe pile is the references for the coefficient of anti-drawing for steel pipe piles. The length of the pile is 42m, and the calculation is under the assumption that uplift bearing capacity for a single pile is 320kN.

For the basement requires overall anti-floating reinforcement, the anti-floating designed water level elevation is calculated to the elevation of the garage entrance. The net reaction force on the floor is 30 kN/m2, and the calculation is under the assumption that uplift bearing capacity for a single pile is 320kN. Also, the spacing between steel pipes is arranged to be 3.3m, meeting the overall anti-floating requirements.

Analysis of pile sinking

Through the analysis of pile pressure, pile sinking time and pressure reloading of 182 steel pipe pile, the process of pressing piles presents the following pattern:

In the process of pressing, the soil around the pile tip is squeezed. When the end of the pile starts to sink, the soil around the pile body is reshaped. After the pile sinks in 2-1 layer with sandy silt, resistance in pile pip is unchanged, but pile side resistance increased. If the pile tip enters No. Three silt clay, the resistance will decrease obviously. It is mainly caused by the sharp decrease of pile tip resistance when it enters the soft soil layer. In the process of continuous pile sinking in silty clay layer, pile pressure gradually increases. After entering the No. 5 clay layer, there will be a sudden change in pile pressure. Then, this pressure will gradually increase, and the piling pressure rises linearly.

After entering the bearing layer of 7-1 silty clay layer, pile pressure suddenly increases when the pile tip touches the hard shell layer. It makes pile sinking difficult, and the piling pressure is more significant than 1,200 KN after the insertion depth is more than 1m. Then, the loading stops. After 24 hours, pile pressure starts to increase, again. Each pile controls the piling pressure based on the standard of cargo, and the characteristic value of the vertical bearing capacity of a single pile is calculated to be 600 kN, which is scientific and reliable.

If there is a rest in the process of pressing pile, pressing strength on the pile will increase significantly. This phenomenon is caused by the increase of friction-induced by the dissipation of excess pore water pressure of soil consolidation. In addition, due to the squeezing effect in the construction site, the piling pressure of the first dozens of piles with the same pile length is smaller than that of the following piles. Five uplift test piles were randomly selected, and 6 Ø22 steel bars were welded on the sidewall of the steel tube to provide reaction force. The relative short piles with less pressing strength were selected for testing. When these five test piles are under the twice of the characteristic value of bearing capacity of 640 kN, the maximum displacement of the single pile is within 1.5cm, meeting the requirements.

4.0 Conclusion

After reinforcement of steel pipe pile in this basement, there are several heavy spots of rain, but no new floating and settlement is discovered. Also, there is no cracks and leakage found after repairing the original beams, columns and plates. It illustrates the reinforcement reaches the expected goals. Moreover, the static pressure steel pipe pile technology used in this project can be used as a reference for similar basement floating accidents in the future.